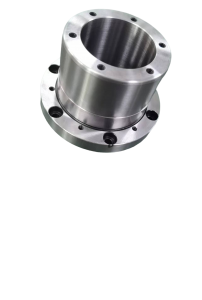

I-CNCturning I-Aluminiyamu eyenziwe ngokwezifiso, insimbi engagqwali, izingxenye zomshini ezinembile Ukwenza imishini

Incazelo Yomkhiqizo

Imishini yokucubungula umshini wokugaya i-cnc / i-CNC lathe / umshini wokugaya / umshini wokugaya / i-lathe / ukusika ucingo njll.

Ingxube ye-aluminium eyenziwe ngokwezifiso:

5052/6061/6063/6065/2017/7075 njll.

Ingxubevange Yethusi:

3602/2604/H59/H62 njll.

Ama-Stainless Steel Alloys:

303/304/316/412/440C njll.

I-Carbon Steel Alloys:

I-Carbon steel/die steel, njll.

Siphatha ezinye izinhlobo eziningi zezinto zokwakha.Uma udinga izinto ezingabaliwe ngenhla, sicela usithinte.

I-Surface Treatment iba mnyama, ipholishiwe, i-Anodized, i-Chrome-plated, i-Zinc-plated, i-nickel-plated, Tinted

I-Inspection Height gauge, i-tooth gauge, insimbi yokulinganisa ividiyo, insimbi yokulinganisa enezinhlangothi ezintathu, njll.

Amafomethi wefayela AutoCAD (DXF, DWG), PDF, TIF, IGS, UG, SolidWorks, njll.

Ungakwazi yini ukuhlinzeka ngokwelashwa okungaphezulu kwezingxenye zomshini ezinembayo?

Sinikeza izinhlobonhlobo zokwelapha ezingaphezulu zezingxenye ezinemba okuphezulu.Ezinye zalezi ziqephu zihlanganisa ukuqhunyiswa kwesihlabathi, ukuxubha, i-electroplating ne-electroplating, i-passivation, i-anodizing, i-chrome plating, ukupholisha, nokunye.Lezi ziqephu zivikela izingxenye ezimweni ezinzima, zithuthukisa ukusebenza kwengxenye noma zithuthukise ukubukeka kwayo kobuhle.

Ngazi kanjani ukuthi imiklamo yami izogcinwa iyimfihlo?(Isivumelwano Sokugcinwa Kwemfihlo)

Njengoba sinedumela lokusebenza ngamakhulu ezinkulungwane zemiklamo eyingqayizivele phakathi neminyaka edlule, sihlala sigcina ulwazi lwamakhasimende luyimfihlo futhi sinezinqubomgomo eziqinile ezisebenzayo ngaphakathi kwezimboni zethu.Uma kudingeka, singasayina ama-NDA namakhasimende adinga le dokhumenti

Ngisithola kanjani isisho sokukhiqiza?

1. Layisha ifayela lakho le-CAD

Isinyathelo sokuqala siwukugcwalisa nje imininingwane yakho bese ulayisha ifayela lakho le-CAD.Lokhu kusisiza ukuthi sakhe imodeli ye-3D yengxenye esiyifunayo noma i-prototype.

2. Ukuhlaziywa kwengcaphuno kanye nomklamo

Emahoreni ayi-12, sizokunikeza isilinganiso kanye nempendulo ye-DFM.Lokhu kuqinisekisa ukuthi iphrojekthi yakho ingenziwa futhi kukunikeza isilinganiso esilungile sezindleko.

3. Oda futhi uqale ukukhiqiza

Uma usuyivumile ikhwothi yakho kanye nomklamo, sizoqala ukukhiqiza i-CNC prototype yakho noma ingxenye yomkhiqizo owenziwe ngomshini we-CNC.

4. Thumela futhi uthole izingxenye zakho

Izingxenye zomshini ze-CNC noma imikhiqizo izokhiqizwa zingakapheli izinsuku.Sikuthumelela nge-express international.Sicela uzizwe ukhululekile ukusinikeza impendulo ukuze wenze isiqiniseko sokuthi ziyahlangabezana nokulindelekile kwakho.

Ukwenza imishini yokunemba kwekhwalithi ephezulu kudinga ikhono elengeziwe lemininingwane kanye nokubambelela kumapulani athile ukuze udale imikhiqizo emangalisayo.Uma ufuna imiphumela emihle, ukusebenza nenkampani ethembekile yokwenza imishini kubalulekile.Sinikezela ngezinsiza eziningi zokunemba zokwenza imishini ezihlanganisa ukujika ngokunemba, ukugaya, kanye ne-EDM ukuze kuhlangatshezwane nezidingo zakho zekhwalithi.

Kusukela ku-prototype kuya ekukhiqizweni, kusuka kucezu olu-1 kuye kwezingu-10,000, sinikeza imishini ye-CNC yokushintsha ngokushesha yezingxenye zakho zensimbi nepulasitiki yangokwezifiso, nokulethwa ngokushesha njengezinsuku ezi-3.

Singakwazi ukukhiqiza izingxenye eziyinkimbinkimbi ezinembayo eziphezulu ezinokubekezelela kwe-dimensional okungu-±0.01 mm, ukubekezelela kwejiyomethri okungu-0.01 mm, irediyasi yemishini encane engu-R0.1mm, kanye nobulukhuni bokusebenza bemishini obungu-Ra0.2μm.Futhi sivame ukubekela inselele izingxenye ze-optical ezinemininingwane enembile.

Hlobo luni lokuqedwa kwangaphezulu olushiywa ukwenziwa kwemishini ye-CNC?

Ngemuva kokuthi inqubo yokukhanda isiqediwe, ingaphezulu lengxenye ye-CNC lizoba namamaki amathuluzi abonakala kancane, abizwa ngokuthi "njengamashini" noma "njengomshini" wokuqeda.Ubulukhuni bomshini (i-Ra) bujwayeleke bube ngu-1.6-3.2 μm, futhi izidingo zokuqedwa kwendawo zingakhushulwa zibe ngu-0.8-1.6 μm noma ngaphezulu ngo-0.2-0.8 μm, kodwa lokhu kuzodinga isikhathi esengeziwe sokusebenza nezindleko eziphakeme.

Siyini isikhathi sakho sokulethwa?

Eqinisweni, asikho isikhathi sokulethwa esijwayelekile, sizohlela ukukhiqiza ngokuhambisana nomsebenzi wamanje.Uma i-oda lakho lokuthenga selitholiwe, imibhalo isiphelile, nezinto zokwakha sezilungile, sizokunikeza impendulo ngokushesha ngesikhathi esiqondile sokulethwa, ngokuvamile esisukela ezinsukwini ezi-3 zebhizinisi kuye emavikini ambalwa, kuye ngobunkimbinkimbi bengxenye nenani lezingxenye ezi-odiwe. .