Ngaphansi kwezimo zokuqina, ukujula okukhudlwana kokusika kusetshenziselwa ukugoqa ukuze kuncishiswe inani lokudlula futhi kuthuthukiswe ukukhiqiza kwe-workpiece;ukuze kuqedwe, ukujula okuncane kokusika ngokuvamile kusetshenziselwa ukuthola ikhwalithi ephezulu yendawo.Okuthinta ukunemba kokugcina komshini nokusebenza kahle komshini wokusebenza, ngaphezu kwezizathu zethuluzi lomshini we-CNC ngokwalo, kufanele futhi lihlanganise izilungiselelo zomzila womshini wokwenza imishini, ukukhethwa kwamathuluzi nokufakwa okulungile, ukukhethwa okunengqondo kwenani lokusika, amakhono okuhlela, kanye nokushesha. ukulawula ukunemba kobukhulu.ukucatshangelwa okuphelele.

1. Amakhono wokuhlela

Uhlelo lwe-NC luwumsebenzi oyisisekelo kakhulu wokwenza imishini ye-NC.Izinzuzo nezingozi zohlelo lomshini wokusebenza kuthinta ngokuqondile ukunemba kokugcina komshini nokusebenza kahle komshini wethuluzi lomshini.Ingaqala ezicini ezimbalwa, njengokusebenzisa ngobuhlakani izinhlelo ezingokwemvelo, ukuncishiswa kwamaphutha anqwabelene ohlelo lwe-CNC, kanye nokusetshenziswa okuguquguqukayo kwezinhlelo ezinkulu nezinhlelo ezincane.

1. Ukusetshenziswa okuguquguqukayo kohlelo oluyinhloko nohlelo oluncane

Ekucubunguleni isikhunta esiyinkimbinkimbi, ngokuvamile sicutshungulwa ngendlela yesikhunta esisodwa nezicucu eziningi.Uma kunokubunjwa okufanayo okuningana esikhunjeni, ubudlelwano phakathi kohlelo oluyinhloko nohlelo oluncane kufanele kusetshenziswe ngendlela eguquguqukayo, futhi uhlelo oluncane kufanele lubizwe ngokuphindaphindiwe kuhlelo oluyinhloko kuze kuqedwe ukucubungula.Ayikwazi ukuqinisekisa kuphela ukuvumelana kobukhulu bokucubungula kodwa futhi ithuthukise ukusebenza kahle kwayo kokucubungula.

2. Yehlisa iphutha lokuqongelela lohlelo lwe-CNC

Ngokuvamile, indlela yokwengeza isetshenziselwa ukuhlela ucezu lokusebenza, olusekelwe ephuzwini langaphambilini.Ngale ndlela, ukwenziwa okuqhubekayo kwezinhlelo zezigaba eziningi nakanjani kuzodala iphutha elithile lokuqongelela.Ngakho-ke, zama ukusebenzisa uhlelo oluphelele lapho uhlela, ukuze ingxenye ngayinye yohlelo isekelwe kucwecwe lokusebenza.Umsuka uwuphawu lokuma, ukuze iphutha elinqwabelene lohlelo lwe-CNC lincishiswe futhi kuqinisekiswe ukunemba komshini.

Ukunemba komshini kusetshenziselwa ikakhulukazi ukukhiqiza imikhiqizo, futhi ukunemba komshini kanye nephutha lomshini amagama asetshenziselwa ukuhlola amapharamitha wejiyomethri wendawo emshinini.Kodwa-ke, amapharamitha wangempela atholwe nganoma iyiphi indlela yomshini ngeke abe nembe ngokuphelele.Kusukela emsebenzini wengxenye, inqobo nje uma iphutha lomshini lingaphakathi kwebanga lokubekezelelana elidingwa umdwebo wengxenye, kubhekwa ukuthi ukunemba komshini kuqinisekisiwe.

Ukunemba komshini kubhekisela kumapharamitha wangempela wejometri (usayizi, umumo kanye nesimo) sengxenye ngemva komshini.Umehluko phakathi kwabo ubizwa ngephutha lomshini.Usayizi wephutha lomshini ubonisa izinga lokunemba komshini.Uma iphutha lilikhulu, kuncipha ukunemba kwemishini, futhi iphutha lincane, kukhulisa ukunemba komshini.Okulandelayo yisingeniso esifushane sezindlela zokuthuthukisa ukunemba kwemishini yama-workpieces:

1. Lungisa uhlelo lwenqubo

I-1): Indlela yokusika isilingo ilungiswa ngokusika isilingo - usayizi wokulinganisa - ukulungisa inani lokuluma kommese wethuluzi - ukusika ngokusika - zama ukusika futhi, njalonjalo kuze kube yilapho usayizi oyifunayo ufinyelelwa.Le ndlela inezinga eliphansi lokukhiqiza futhi isetshenziselwa ikakhulukazi ukukhiqizwa kweqoqo elincane lesiqephu esisodwa.

2): Indlela yokulungisa ithola usayizi odingekayo ngokulungisa kusengaphambili izikhundla ezihlobene zethuluzi lomshini, isihluthulelo, isiqeshana somsebenzi kanye nethuluzi.Le ndlela inokukhiqiza okuphezulu futhi isetshenziselwa ukukhiqiza ngobuningi.

2. Yehlisa iphutha lethuluzi lomshini

--Ukunemba kokuzungezisa kufanele kuthuthukiswe

①Khetha amabheringi okunemba okuphezulu

②Kusebenzisa ukunemba okuphezulu kwe-multi-oil wedge ashukumisayo yokucindezela amabheringi

③ Ukusebenzisa amabheringi e-hydrostatic anembe kakhulu

--Thuthukisa ukunemba kwezesekeli ezinama-bearings

①Thuthukisa ukunemba komshini kwezimbobo zokusekela amabhokisi namajenali okuphotha

②Thuthukisa ukunemba komshini wendawo yokukhwelana ngokuthwala

③ Linganisa futhi ulungise ububanzi bokuphuma kwe-radial bezingxenye ezihambisanayo ukuze wenze iphutha libe nesinxephezelo noma ukulinganisa

--Layisha ngokufanelekile i-average eginqikayo

①Ingakwazi ukuqeda igebe

②Khulisa ukuqina kokuthwala

③ Iphutha le-Homogenization yesici esigingqikayo

--Ukunemba kokujikeleza kokuphotha akuboniswa kucezu lokusebenza

3. Yehlisa iphutha lokudlulisela leketango lokudlulisela

(1) Inani lezingxenye zokudlulisela lincane, iketango lokudlulisela lifushane, futhi ukunemba kokudlulisela kuphezulu

(2) Ukusetshenziswa kokudlulisa ukusheshisa kuyisimiso esibalulekile sokuqinisekisa ukunemba kokudlulisela, futhi lapho ipheya yokudlulisela isondela ekupheleni, isilinganiso sokudlulisela kufanele sibe sincane.

(3) Ukunemba kwesiqephu sokuphela kufanele kube phezulu kunezinye izingxenye zokudlulisela

Okwesine, nciphisa ukuguga kwamathuluzi

(1) Ithuluzi kumele lilolwe kabusha ngaphambi kokuba usayizi wethuluzi uguge ufinyelele esigabeni sokuguga ngokushesha

(2) Khetha amafutha okusika akhethekile ukuze ugcobe ngokugcwele

(3) Izinto ezisetshenziswayo kufanele zihlangabezane nezidingo zenqubo

5. Yehlisa ukucindezeleka kanye nokuguqulwa kwesistimu yenqubo

(1) Ukuthuthukisa ukuqina kwesistimu, ikakhulukazi ukuqina kwezixhumanisi ezibuthakathaka ohlelweni lwenqubo

(2) Yehlisa umthwalo nezinguquko zawo

6. Yehlisa ukuguqulwa kokushisa kwesistimu yenqubo

(1) Nciphisa ukukhiqizwa kokushisa komthombo wokushisa futhi uhlukanise umthombo wokushisa

(2) Inkambu yokushisa yokulinganisa

(3) Thola ukwakheka kwengxenye yethuluzi lomshini elinengqondo kanye nebhentshimakhi yokuhlanganisa

(4) Sheshisa ukuze uzuze ukulingana kokudlulisa ukushisa

(5) Lawula izinga lokushisa lendawo

Okwesikhombisa, nciphisa ukucindezeleka okusele

(1) Ukwandisa inqubo yokwelapha ukushisa ukuze kuqedwe ukucindezeleka kwangaphakathi;

(2) Hlela ngokunengqondo inqubo yezobuchwepheshe.

Okungenhla kuyindlela yokunciphisa iphutha le-workpiece, futhi ukuhlelwa okunengqondo kwenqubo kungathuthukisa ngokuphumelelayo ukunemba kwe-workpiece.

Okuningi mayelana nalo mbhalo womthomboUmbhalo womthombo uyadingeka ukuze uthole ulwazi olwengeziwe lokuhumusha

Thumela impendulo

Amaphaneli aseceleni

Umlando

Kulondoloziwe

Faka isandla

2. Ukulungiselelwa okunengqondo kwemizila yokucubungula

Ukulungiselelwa okunengqondo kokucubungula umzila nokulandelana kokucubungula kuyisisekelo esibalulekile sokuthuthukisa uhlelo lokucubungula ucezu lokusebenza.Kungacatshangelwa esicini sendlela yomshini kanye nendlela yokondla.

Lapho wenza i-CNC Milling ye-workpiece, kuyadingeka ukukhetha indlela efanele yokuphakelayo ngokuya ngezidingo zobuchwepheshe ze-workpiece ukuqinisekisa ukunemba kokusika nokusebenza kahle kocwecwe lokusebenza.Lapho ukugaya i-contour yangaphandle ye-workpiece yendiza, imizila yokusika nokusika yethuluzi kufanele ihlelwe.Zama ukusika futhi uphume ngomugqa wokunweba wejika lekhonta ukuze ugweme izimpawu zommese lapho kuhlangana khona.Ngesikhathi esifanayo, ekugayeni, ukugaya phansi noma ukugaya phezulu kufanele kukhethwe ngokuvumelana nesimo se-workpiece.

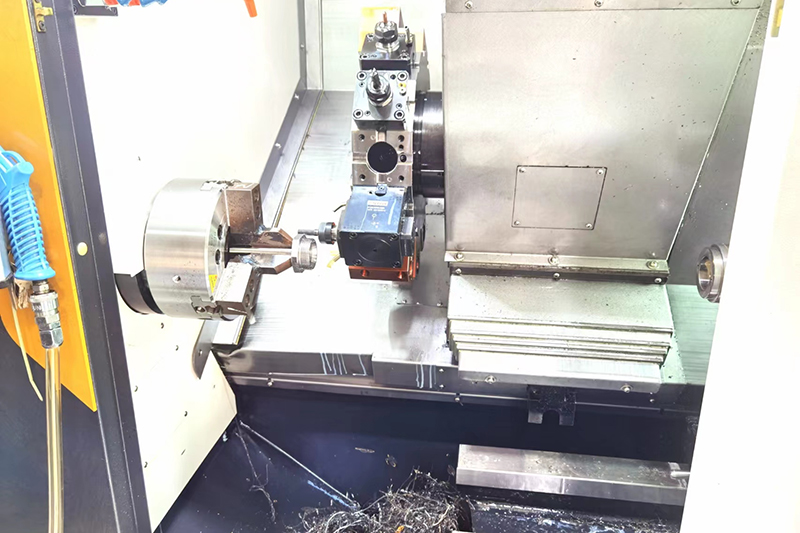

3. Ukukhetha ithuluzi nokufaka okulungile

Kungakhathaliseki ukuthi i-CNC machining noma i-machining evamile, ithuluzi lisebenza ngokuqondile kucezu lokusebenza, ngakho ukukhethwa nokufakwa kwalo yizinto ezibaluleke kakhulu zokunemba komshini kanye nekhwalithi ephezulu yendawo yokusebenza.Ikakhulukazi lapho i-workpiece icutshungulwa esikhungweni semishini ye-CNC, amathuluzi agcinwa kumagazini wamathuluzi kusengaphambili, futhi uma ukucubungula kuqala, awakwazi ukushintshwa ngokuthanda kwakhe.Ngakho-ke, isimiso esijwayelekile sokukhethwa kwamathuluzi siwukuthi: ukufakwa kalula nokulungiswa, ukuqina okuhle, ukuqina okuphezulu nokunemba okuphezulu.

4. Ukukhetha okunengqondo kwenani lokusika

Ukunqunywa kwenani lokusika kuyingxenye ebalulekile yenqubo yemishini ye-CNC.Ubukhulu bayo buyipharamitha ebalulekile yokunyakaza okuyinhloko kanye nokunyakaza kokuphakelayo kwethuluzi lomshini, futhi kunomthelela obalulekile ekunembeni komshini, ukusebenza kahle komshini kanye nokugqoka kwamathuluzi we-workpiece.Ukukhethwa kwenani lokusika kuhlanganisa isivinini sokusika, inani lokusika emuva kanye nenani lokuphakelayo.Isimiso sokukhetha esiyisisekelo sithi: uma ukuqina kuvumela, ukujula okukhulu kokusika kusetshenziselwa ukugoqa ukuze kuncishiswe inani lokudlula futhi kuthuthukiswe ukukhiqiza komsebenzi;ukujula okuncane kokusika ngokuvamile kusetshenziselwa ukuqedela ukuthola ikhwalithi ephezulu yendawo.

Isikhathi sokuthumela: Sep-26-2022